Here at the Soundproofing Store we receive many enquiries about music rehearsal rooms and recording studios. One of the mos popular enquiries is for drum rooms. Due to the nature of an acoustic drum kit, they tend to create a lot of airborne noise and also a lot of vibration due to the kick drum.

So...if you are a drummer, or maybe have a child or family member that has taken up playing drums at home or maybe you are a school music department with a drum room, how do you reduce the amount of noise that escapes the drum room and disturbs other people?

Well, there are a few things to consider, but I will guide you through the important points.

First, here are the main

fundamental physics we need to consider.

"Room within a room?"

For live music levels of noise we need to build a "

room within a room ", with the inner room decoupled or isolated from the outer room. We do this by using a system such as our

ReductoClip system . These are fixed to the solid wall and ceiling joists, we can then build new wall and ceiling layers (creating the inner room), by fixing these layers onto the ReductoClip rather than being fixed directly to the wall. The ReductoClip act like shock absorbers, so when sound hits the new wall layers and turns into a vibration energy, the ReductoClip absorb this energy stopping it from transferring into the structure.

We then need to add high mass materials such as two layers of 15mm acoustic grade plasterboard which has a higher mass than standard plasterboard. You can also improve the performance by adding different materials (different types of mass block different sound frequencies better than others). These include

FlexiSound 5 .

On Solid Walls - We get the highest performance by building a timber frame 10mm in front of the existing wall, isolating the frame from the surrounding surfaces using

isolation strip . We then fill the frame with

acoustic mineral wool and then fix the ReductoClips and furring channels to the frame.

On Stud Walls - We remove the plasterboard layer of the wall to expose the timber frame inside. We then fill the frame with acoustic mineral wool and add our

ReductoClips to the frame.

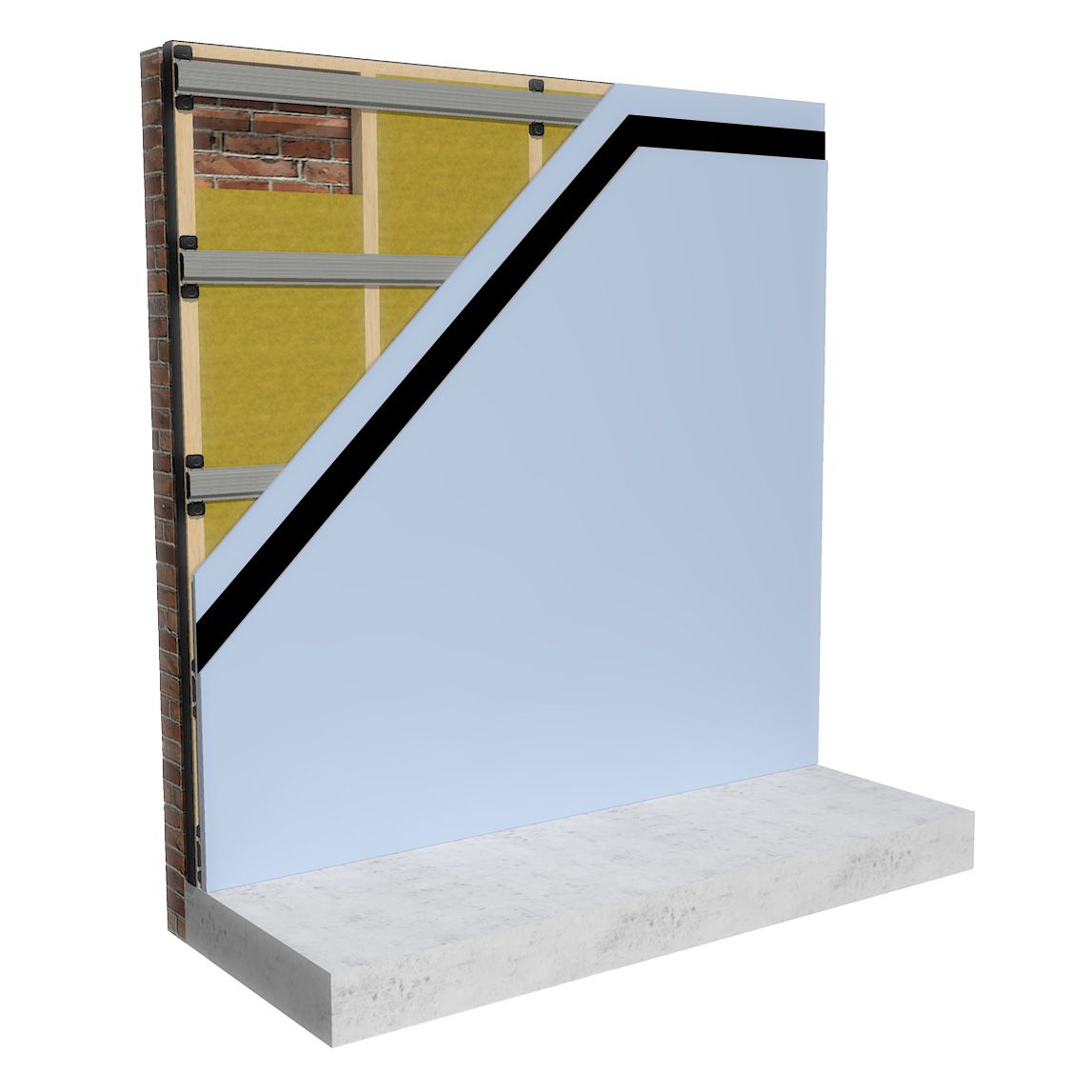

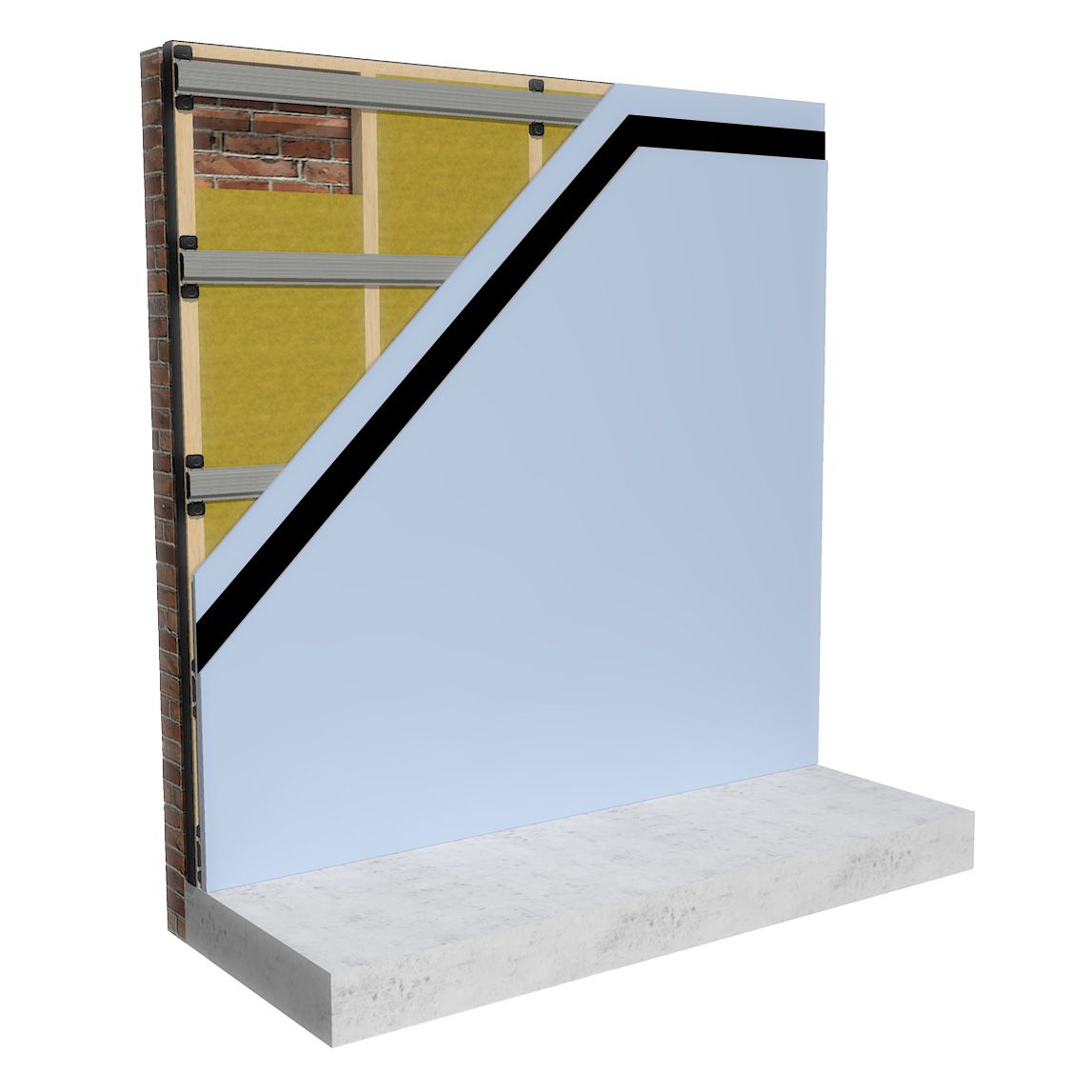

Fully Isolated Clip and Bar System (120mm Thick):

1. Independent Stud Frame - 10mm air gap isolates the soundproofing from the offending wall for best possible sound reduction performance

2. Isolation Strip - isolates from surrounding surfaces to reduce flanking vibration

3. ReductoClips - decouple the mass layers from the frame and act like a shock absorbing suspension system to dampen high levels of sound energy and vibration

4. ReductoClip Furring Channels - extra wide to make fixing acoustic plasterboards quicker and easier

5. Acoustic Mineral Wool - dampens sound within the frame cavity to stop sound amplifying

6. Acoustic Plasterboard - (2 layers) to increase the mass of the wall. More mass and density than standard plasterboard but with the same finishing and decorating techniques

7. FlexiSound 5 - Anti-Vibration membrane to add further mass to the wall. A different type of mass to reduce different sound frequencies to the other layers. FlexiSound also helps to dampen sound energy and vibration

Ceilings

We use the same technique on the ceiling to block sound travelling above.

On a Timber Joist Ceiling -

We remove the current plasterboard layer exposing the timber joists. We fill between the joists with acoustic mineral wool and add the ReductoClips

to the bottom of the joists.

On a Concrete Ceiling

- We can fix the ReductoClips

directly to the ceiling.

Floors

If the drum room is situated in a house or building with rooms below, then there are a couple stages. Firstly, we need to add acoustic mineral wool under the floorboards to stop sound resonating in the void space below the floor. We then need to add mass to the floor to block the airborne sound, and a resilient layer to absorb the vibration from the kick drum. I would recommend one of our SoundMat solutions, preferably the

SoundMat 3 Plus for the highest performance.

If the drum room is on the ground floor with a solid, concrete floor, then you will just need to add a mat that will absorb the vibration and stop it from transferring into the structure. I would recommend our

ImpactoMat 5mm .

Doors and Windows

These are the biggest weak spots. Ideally, if you can get away with not having any windows, this will give you the best performance. If you need natural light then use triple glazed or specialist acoustic glazing. This needs to be well fitted with no gaps between the frame and the wall.

Regarding Doors, again you need high mass material, so a heavy, dense fire door, or even a double door system would be best. Or you can add mass to your existing door by adding a layer of

mass loaded vinyl to the door. Again making sure there are no air gaps between the door and frame by adding a good seal or draught excluding material. You can also purchase custom made

acoustic doors which are very high performing, but these can be expensive.

Ventilation

For ventilation we suggest using a high quality

acoustic vent system .

I hope this has covered most questions, as always if you want the best advice, speak to a professional. We are happy to talk you though any problems or answer any questions.

You can call us Monday to Friday, Nine to Five on 01423 206 208 or contact us using the page below.

"We don’t expect you to become an overnight expert in soundproofing, that’s what we’re here for."

We let our customers do the talking

Mon - Fri: 9:00am - 5:00pm

Sat - Sun: Closed

Join Our Newsletter

Thank you for contacting us.

We will get back to you as soon as possible

www.soundproofingstore.co.uk

01423 206208

sales@soundproofingstore.co.uk