How to soundproof a stud wall

To soundproof a stud wall, decouple and enhance its ability to absorb and dampen sound energy. Sound travels through solid materials via contact so decoupling can be achieved by building a new stud wall with a gap, making it harder for vibration to travel.

Adding resilience allows the wall to flex and dampen the vibration (similar to how the suspension springs in a car help to absorb bumps in the road) while adding extra layers of mass helps to block airborne noise (different types of mass block different frequencies of sound).

Reduce the amplification of sound within the sealed cavity by adding acoustic insulation such as mineral wool between the stud frame.

The 4 main principles of stud wall soundproofing:

1. Isolation

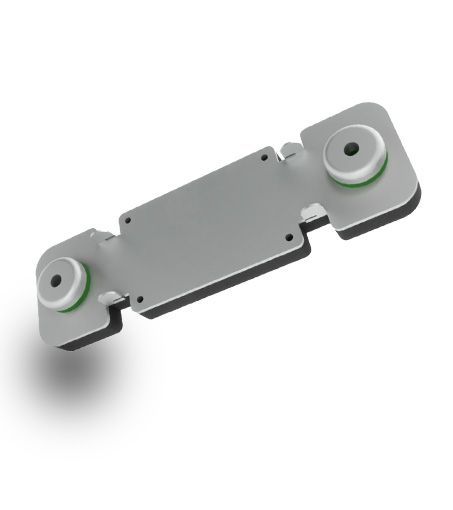

Isolate or 'decouple' soundproofing by leaving a physical gap between the structure and the soundproofing layers to create a sound breaker.

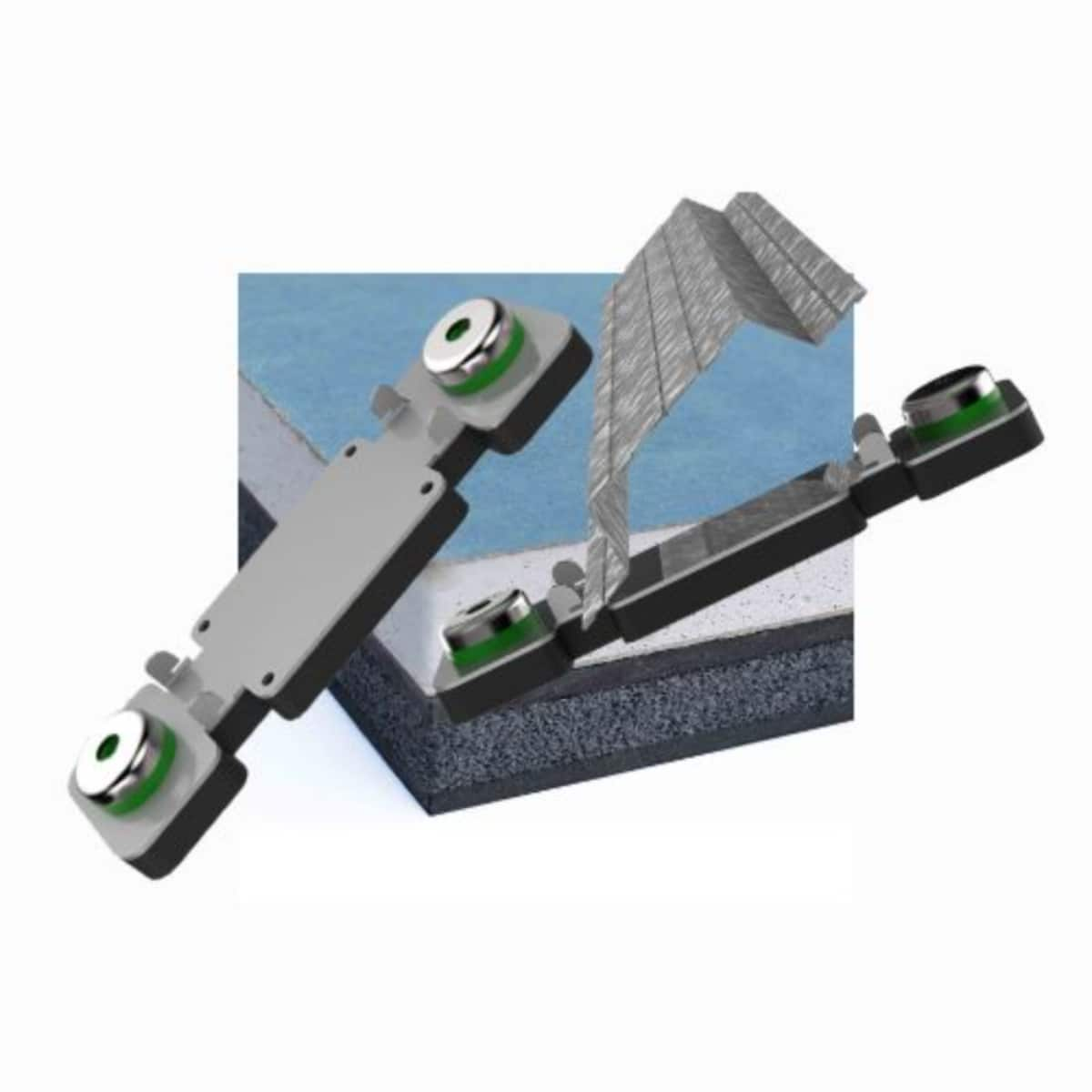

ReductoClips are extremely effective at isolating soundproofing layers from the offending walls

2. Damping

Use elastic or damping materials like FlexiSound and Closed Cell Foam.

ReductoClips also provide excellent damping as they help to absorb sound energy and vibrations

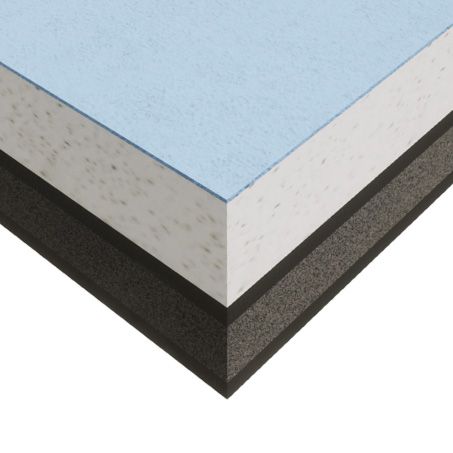

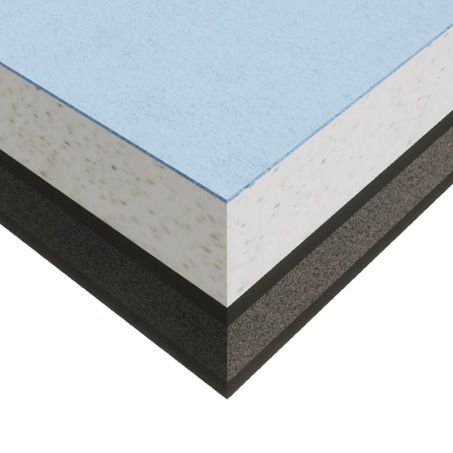

3. Mass

Increase the density of stud walls to help reduce unwanted airborne noise. Using materials like Mass Loaded Vinyl, FlexiSound and Acoustic Plasterboard.

Direct to wall soundproofing panels like SoundBoard 4 combine key materials in one easy to install stud wall soundproofing solution. This combination of different types of mass helps to block different frequencies of sound

4. Insulate Cavities

Add acoustic mineral wool within stud cavities to help absorb sound

We don’t expect you to become an overnight soundproofing expert, that’s what we’re here for.

Stud Wall FAQs

Visit the Knowledge Hub for more in depth info about how soundproofing works