9 ways to soundproof an existing internal wall

The best way to soundproof an existing wall is to:

- Add mass to the existing structure to block airborne sound

- Add different types of mass. Simply adding more of the same won't double the performance

- Decouple the soundproofing from the existing wall

- Build a stud or metal frame in front of the existing wall

- Add insulation to stud walls

- Don't use acoustic panels designed for sound absorption

- Install the soundproofing correctly, without any gaps or holes

- Choose the correct system for the level and type of noise needing to be blocked

- Use a proven and tested soundproofing solution like the ProSound™ ReductoClip™

Soundproofing a wall is like baking a cake

Think of soundproofing an existing wall like making a cake.

To bake the perfect cake you need lots of different ingredients. Once you have the ingredients it's important to add the right amount of ingredient in the correct order. A bowl of flour on its own, regardless of how much you use, will only ever be a bowl of flour, it will never be a cake. Key soundproofing materials like FlexiSound, acoustic plasterboard, mass loaded vinyl, are all brilliant ingredients, but they need to be used in the right combination in the right quantities to become an effective soundproofing solution. The Soundproofing Store have created the perfect soundproofing solutions (like the perfect ready made recipe), simply follow the instructions of our tried and tested systems and voila!

1. Add mass to existing internal walls

If your existing wall is a brick party wall between you and your neighbour or a stud wall within your own home one of the key elements of soundproofing is to add mass to the wall. Adding mass is key to blocking airborne noise such as voices, and TV noise. This is why the majority of acoustic soundproofing panels are made from acoustic plasterboard rather than standard plasterboard. Acoustic plasterboard has a higher density core than standard plasterboard and therefore adds more mass to a wall which makes it harder for sound to travel through. Adding mass to an existing wall works particularly well for higher frequencies. However, lower bass frequencies will need to be blocked by more than just mass. Using acoustic plasterboard rather than standard plasterboard will help increase the mass of the wall, but isn't a soundproofing solution in itself. Think back to the cake analogy - there are some other key ingredients which also need to be added.

Learn more about why simply adding acoustic plasterboard to an existing wall is not the most effective way to soundproof a wall:

2. Add different types of mass to soundproof an existing wall

When adding mass to an existing wall to block airborne noise, to further improve the results it is more effective to add different types of mass., rather than just more of the same. There are diminishing returns for each additional layer of simply adding more of the same material.

This is because different materials block different types of sound waves. Heavy materials which are good at blocking noise include; mass loaded vinyl, acoustic plasterboard and FlexiSound 5.

3. Decouple soundproofing from the existing internal wall

The best way to stop sound vibrations from passing through an existing wall is to decouple any soundproofing from the original structure, as sound vibrations travel more easily through two surfaces that touch.

Did you ever do the experiment at school with two baked bean cans and a piece of string which acts like a very basic telephone? Sound waves travel through the string and the vibrations from the first can continue down the string producing sound waves meaning the second person can hear what the first person is saying. If the string is cut, there is nowhere for the sound to travel from one can to another, basically the pathway for the sound waves has been decoupled and the vibrations are stopped.

In soundproofing decoupling from the existing wall can be done with the ReductoClip and furring bar system. More details below..

4. Build a stud or metal frame in front of the existing wall

We know it's important to decouple soundproofing from the existing wall, as this helps to eliminate impact noises and reduce airborne noise. So, how is this done and what is the most effective way of doing it?

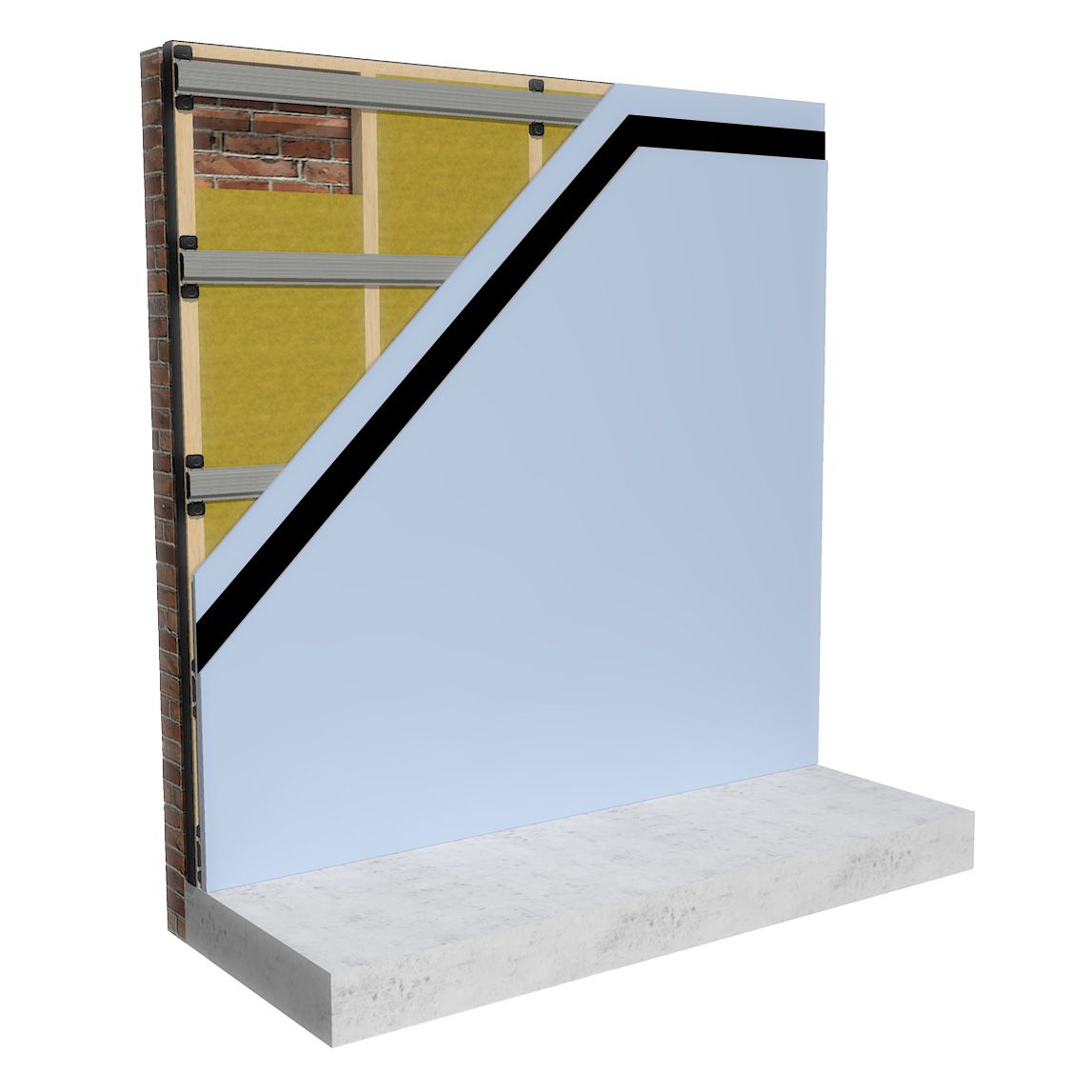

There are various clip and bar soundproofing solutions on the market and our recommendation would be to use the market leading ReductoClip System. The ReductoClip System can be applied directly to an existing brick wall, or to further enhance the performance, attached to an independent stud frame, which is built a minimum of 10mm in front of the existing wall. The stud frame attaches to the ceiling, floor and side walls, but doesn't touch the offending wall (the one needing to be soundproofed).

This increases the performance of the soundproofing as it provides an air gap between the offending wall and the soundproofing which makes it harder for the sound to pass through.

The ReductoClips and furring bars are then attached to the stud frame, which further isolates the soundproofing from the existing wall. This is the highest level of soundproofing and this independent system is also used in music studios and to block excessive levels of noise in domestic homes.

The ReductoClip System works by isolating existing walls which reduces the transference of sound vibration energy:

- A timber stud frame is built a minimum of 10mm in front of the existing wall

- ReductoClips and furring bars are attached to the stud frame which decouple the layers of soundproofing

- Acoustic mineral wool is added in between the stud frame battens which absorbs airborne sound in the cavity between the soundproofing and the existing wall

- Acoustic plasterboard is attached to the furing bars, which is 50% denser than standard plasterboard and adds much more mass to the existing wall

- A layer of FlexiSound is added to the acoustic plasterboard, which again adds a huge amount of mass

- A second layer of acoustic plasterboard is added sandwiching the FlexiSound in between

Back to the cake analogy, above is the correct ingredients, added in the correct order, to achieve the highest levels of soundproofing on an existing wall.

Learn more about the ReductoClip System v's other clip systems

Installing the ReductoClip Independent Wall System

5. Add insulation when soundproofing a stud wall

If the existing wall you are wanting to soundproof is a stud wall, rather than a solid brick wall, then it is important to firstly insulate the cavity. The recommendation would be to remove the plasterboard on one side of the existing wall and fill the exposed frame with acoustic mineral wool, this absorbs any sound which gets inside and stops the sound from resonating and amplifying in the void.

Plasterboard is then added back onto the wall. The next stage follows the same principle as when soundproofing a solid existing wall, which is to add mass and different types of mass. The Soundproofing Store have an award winning direct to wall acoustic solution called the SoundBoard 4, which adds a great deal of mass to block airborne sound, whilst the closed cell foam within the acoustic board also helps to absorb vibrations.

SoundBoard 4 is only 30mm thick and is attached directly to the existing wall. The soundproofing panel is made up of 4 layers (4 ingredients, of the correct quantities, in the correct order):

- 15mm Acoustic Plasterboard

- 3mm Mass Loaded Vinyl

- 9mm Closed Cell Foam

- 3mm Mass Loaded Vinyl

Why acoustic mineral wool is used in soundproofing

The 3 best ways to soundproof a stud wall

How to soundproof an existing internal stud wall

6. Soundproofing an internal wall with acoustic panels

There can often be a crossover in terminology when looking at soundproofing and sound absorption. Often acoustic panels are a sound absorption product, but sometimes come under the overall heading of soundproofing.

Most commonly acoustic panels are used in sound absorption. Sound absorption uses acoustic wall and ceiling panels to absorb sound energy to reduce echo and reverberation within a room

Soundproofing is different to sound absorption because soundproofing is designed to stop sound energy from travelling through one structure into another. Soundproofing can block sound from entering a room and at the same time block it from leaving a room.

If you are experiencing echo and noise in a communal area such as an office, school, village hall or restaurant, then to help with the echo and levels of noise within the room you would be looking at sound absorption.

If, however you have the unwanted noise from noisy neighbours through a party wall, floor or ceiling and you want to block that unwanted noise, then you would be looking at soundproofing.

The difference between soundproofing and sound absorption

7. Install soundproofing correctly

The beauty of the soundproofing solutions available at The Soundproofing Store is that they can all be installed by a competent DIYer. Over 80% of customers install soundproofing to an existing wall themselves. Detailed videos and installation guides are readily available and our technical team are on hand to answer any questions. For customers who don't feel confident installing soundproofing themselves, then it is very easy to ask a recommended local trades person, who will have no difficulty in installing the acoustic solutions.

Installing soundproofing isn't a trained skill, so anyone with experience of fitting plasterboard will find installing soundproofing solutions relatively easy.

When installing soundproofing it is important to think of it like waterproofing. Any weaknesses in the installation, or gaps will allow sound to leak out.

8. Choose the correct solution for your noise issue

There are different soundproofing solutions depending on the type of noise and level of noise you are trying to block. Sometimes there can be other considerations, such as how much space you have to lose. For example, the ReductoClip Independent System takes up 120mm and is the highest performing system. This is the equivalent of a soft drinks can laid on its side. There are occasions when this system simply isn't viable and a slimmer system is required. In this instance the ReductoClip Direct to wall solution can be used. The same as the ReductoClip Independent System, but without the stud frame, ReductoClips are attached directly to the wall, which still delivers a high level of soundproofing, but not as high performing as the independent system. Space loss is only 60mm and for performance v's space loss then this is an excellent solution.

There are many direct to existing wall solutions, including the SoundBoard 4, which is only 30mm thick. These acoustic boards are great on stud walls, where there is already little mass and the wall is naturally performing badly at blocking sound. Adding the SoundBoard 4 will give a good improvement against airborne noise. Direct to wall boards are effective at blocking higher frequency airborne sounds, however, because they don't decouple from the original structure like the ReductoClips do, then the direct to wall boards panels should not be used in instances where impact vibrations, or loud levels of noise need to be blocked. Impact vibrations include not only loud music and bass tones, but also the likes of snoring, or deep voices. If there is any doubt as to whether the system you are considering will perform to your expectations and block the unwanted noise you are experiencing, then it is always best to speak to an expert.

Acoustic soundproofing panels overview

The below video highlights the features of the SoundBoard 4 direct to existing wall soundproofing panel. It also highlights the instances it shouldn't be used in. Such as blocking impact vibrations, loud noise and low bass frequencies. If these are the types of noises being heard through an existing wall, then a higher performing solution such as the ReductoClip System will be required.

9. Use a proven and tested soundproofing solution

Cheap alternatives exist under the 'soundproofing' umbrella. We speak to many customers who have purchased an inferior solution elsewhere, or installed a solution which isn't designed to block the level of sound they are needing to block. Our advice would be to do it once and do it right. Using cheaper alternatives, making up your own system, or only using part of a system usually ends up with customers having to spend more in the long run. The cake analogy comes back to play here, you need the right and different types of soundproofing materials, the correct quantity of materials, in the right order and installed in the right way.

if there is any doubt as to which soundproofing solution should be used for your individual noise issue when soundproofing an existing wall, then our recommendation would be to always speak to an expert.

Share

"We don’t expect you to become an overnight expert in soundproofing, that’s what we’re here for."