The 3 best ways to soundproof a stud wall

Differences between stud and solid walls

Stud walls are usually internal walls separating living spaces within the same property. Solid walls on the other hand are usually made of brick and separate attached properties. If you live in a terraced property, the wall separating you and your neighbours property (even though they are attached) will be a solid brick wall.

The internal walls separating e.g. bedrooms, bathrooms to your bedrooms, or the kitchen to your lounge will usually be stud walls.

Stud wall soundproofing common scenarios

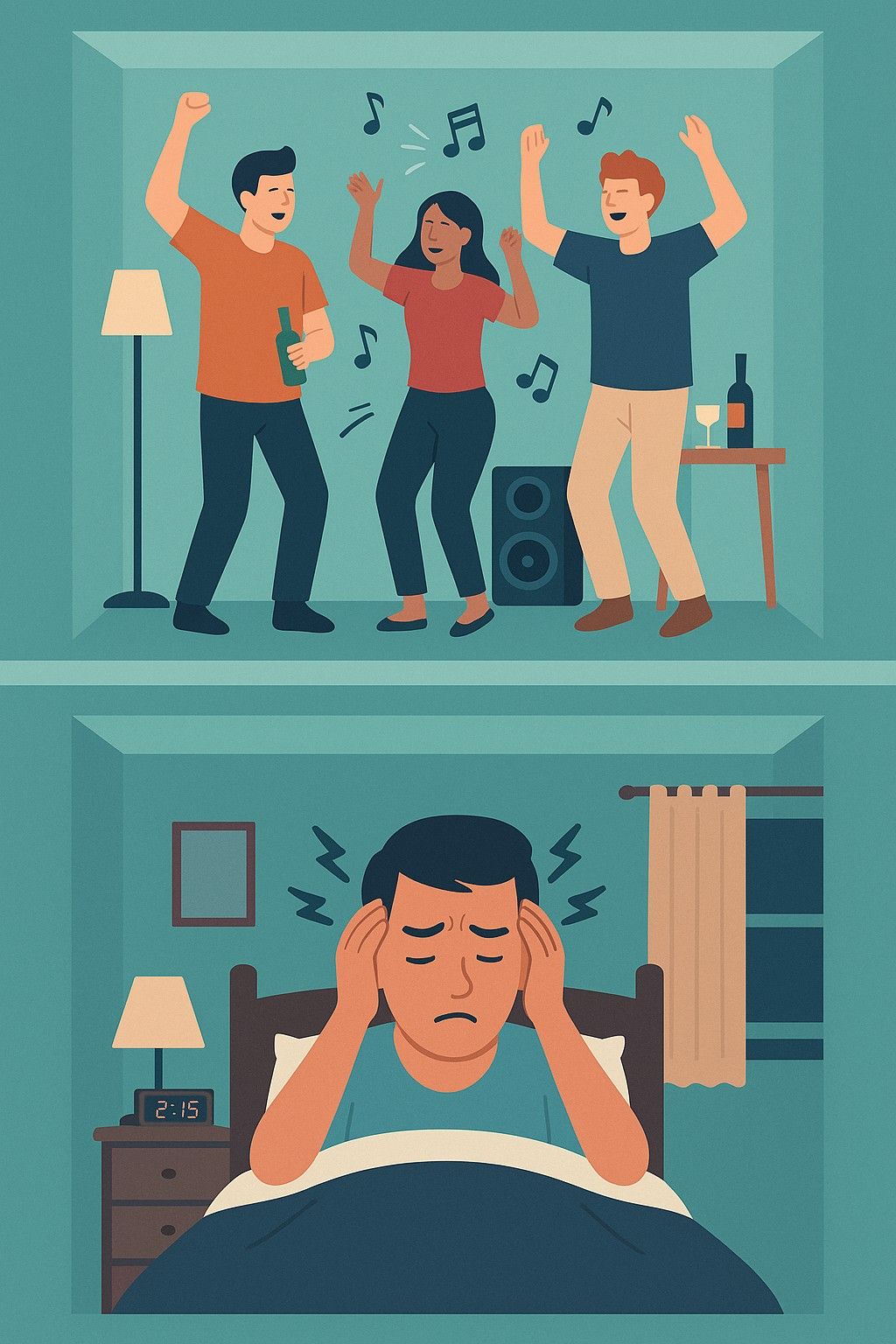

There are a range of situations when soundproofing an internal stud wall becomes a necessity. These commonly range from wanting to soundproof the connecting stud wall between bathrooms and bedrooms. It might also be the separating wall between bedrooms to reduce the unwanted noise of e.g. snoring coming from an adjoining room. Also popular, is the soundproofing of children's games rooms and play rooms from connecting rooms in the house.

Soundproofing stud walls

There are two main differences between a solid wall and a stud wall when it comes to sound:

1. Stud walls are hollow. The empty space within the frame creates a sealed chamber where the sound bounces around, echoes, and amplifies becoming even louder. This is called the drum effect because that’s exactly how a drum works. If you want to see the drum effect in action, the video below goes into more detail.

2. Stud walls are very lightweight. This is a problem because mass plays a huge part in blocking sound. The heavier, and more dense the wall is, the harder it is for sound to pass through. A solid brick or concrete wall has a much better starting point than a stud wall because it already has much more mass. Therefore, to effectively soundproof a stud wall, a lot of extra mass needs to be added to the wall.

Sound energy and vibration

Sound is a physical energy (a vibration) and sound vibrations travel through solid materials and through the contact of solid materials. To stop the sound coming through an internal stud wall, it's important to stop the vibration from coming through.

There are two ways to reduce this vibration:

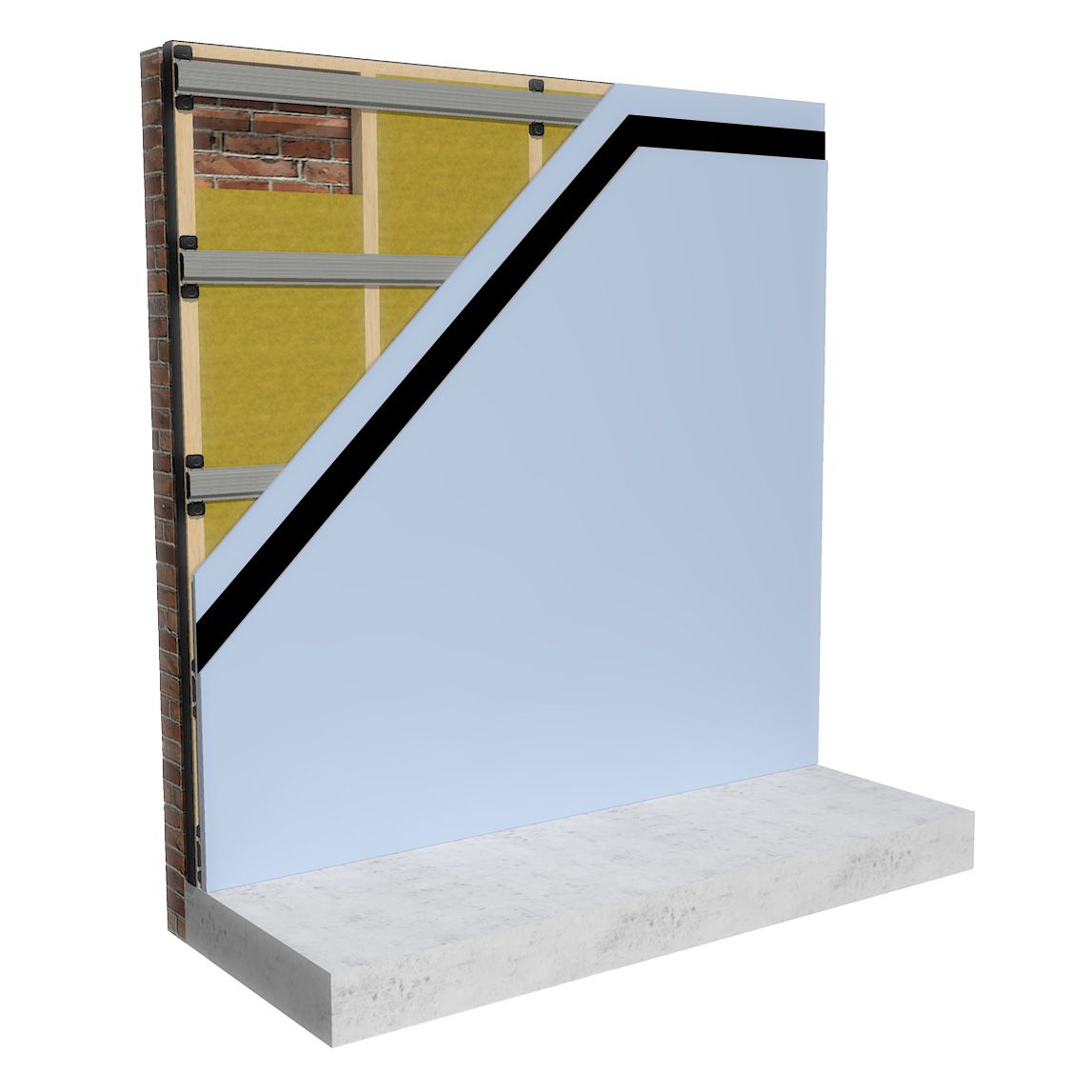

1. The best way is through de-coupling. In other words, building another wall in front of the existing wall with a gap in between so they are completely disconnected. This makes it much more difficult for the vibration to travel through as it has to jump across a physical gap.

2. Add resilience to the wall, which allows the wall to flex and dampen the vibration.

So how is this achieved? The three most effective soundproofing solutions for stud walls are highlighted in more detail below.

How to soundproof an existing stud wall

The first step when soundproofing a stud wall is to fill the depth of the frame with a high density acoustic mineral wool. This absorbs the sound that gets inside and stops the sound from bouncing around and amplifying.

This alone isn’t going to block the sound, but helps to minimize the drum effect before adding a soundproofing solution to the wall and will lead to a higher sound reduction in the end.

In the majority of cases when soundproofing an existing stud wall it is more common to treat one side. If building a new stud wall, or if able to treat both sides, then the following still applies, but there may be a little more flexibility.

The benefits of using acoustic mineral wool in soundproofing and the drum effect

1. SoundBoard 4 Direct to Stud Wall Soundproofing Panel

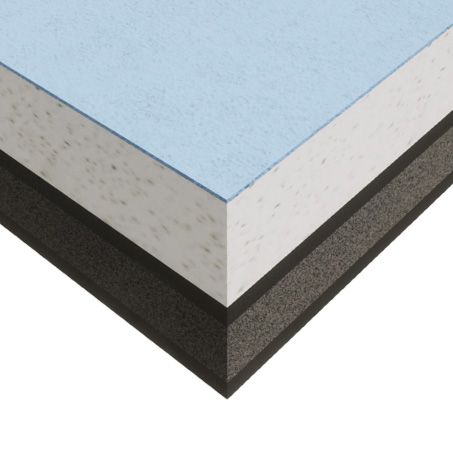

The most popular and most cost effective solution, is the ProSound SoundBoard 4. This is a 30mm thick direct to wall soundproofing panel and is installed as one single, easy to install panel.

SoundBoard 4 is made up of 4 layers consisting of a 3mm mass loaded vinyl, a 9mm closed cell acoustic foam, another 3mm mass loaded vinyl and finally a 15mm acoustic grade plasterboard. The acoustic plasterboard and the mass loaded vinyl layers add an extra 29kg of mass per meter square to the wall and add different types of mass to block different frequencies of sound. The closed cell foam separates the hard plasterboard layer from the stud wall and adds some resilience, which helps to dampen some of the sound energy.

The SoundBoard 4 is easily installed directly onto the stud frame. For an even higher performance, you can cover the stud frame with a layer of acoustic grade plasterboard first, then install the SoundBoard 4 over the top and this gives you even more mass.

For domestic properties wanting to reduce standard household noise between rooms, SoundBoard 4 is a thin, simple and effective solution.

How to soundproof an existing stud wall with SoundBoard 4

2. ReductoClip Direct to Stud Wall Soundproofing System

If a higher level of sound reduction is needed, the next level up is the ReductoClip Direct to Stud Wall System. ReductoClips are fixed onto the front of the stud frame and act like shock absorbing brackets. ReductoClip furring channels are then easily inserted into the clips to allow for somewhere to fix the acoustic plasterboard layers to. The wall is then covered with a layer of 15mm acoustic grade plasterboard, a layer of FlexiSound membrane, and then a final layer of 15mm acoustic plasterboard. These layers add an extra 35kg of mass per meter square to the wall, and combine different types of mass to block different frequencies of sound.

The ReductoClip Direct to Stud Wall System de-couples the mass layers from the stud frame, and gives the system resilience and flexibility to dampen high levels of sound energy. A useful analogy of how it works is to think about how the suspension springs in your car dampen the impact of potholes and bumps in the road to give you a smoother ride. The ReductoClip System dampens and absorbs the energy of the soundwaves that hit your wall.

This system is 60mm thick, which is the slimmest system of its kind on the market, so if you can afford to take up 60mm of space, this system will give you a very high level of sound reduction. The ReductoClip Direct to Wall System will achieve a higher performance than the SoundBoard 4, particularly for lower frequency sounds such as low male voices, snoring, or bass from music or TV.

3. ReductoClip Independent Stud Wall System

The final soundproofing option for stud walls is a little more extreme and more aimed at people trying to block out loud music, or heavy bass. This could be for people building a home cinema room or music space within their home, or if you just want to achieve the highest possible sound reduction you can.

This is using the ReductoClip Independent Stud Wall System. The same system as the ReductoClip Direct to Wall System, but this time, instead of installing it directly onto the existing stud wall, the existing plasterboard is removed and the frame is filled with acoustic mineral wool (the same as with our previous options) then a gap of at least 10mm is left and then a new stud frame is built in front of (but not touching) the existing stud wall. This achieves a complete de-coupling. The new frame is then filled with acoustic mineral wool and the ReductoClip System is installed onto the new frame.

Again, this adds a high level of resilience and a high level of mass. Still the slimmest clip and bar system on the market, this is going to take up 120mm space including the decoupling element, but delivers by far the highest level of sound reduction.

Frequently asked questions when soundproofing a stud wall:

1. How do you decorate a soundproofed stud wall?

All three stud wall soundproofing solutions have a 15mm acoustic grade plasterboard finish. This means they are decorated just as you would standard plasterboard. Usually a skim plaster on top of the plasterboard to cover any screw holes or joins. This then provides a flat even surface which can be painted, or wallpapered. For wallpaper, the recommendation would be to use a heavy-duty dry lining wallpaper first prior to the final wallpaper finish.

2. Should I insulate the cavity of my stud wall?

Yes. As highlighted in this article, the recommendation would be to use acoustic mineral wool to insulate the cavity prior to soundproofing. If this isn't done, the cavity can act as a sealed chamber with the sound amplifying and resonating inside.

3. Can I install the soundproofing myself?

The ReductoClip stud wall solutions and SoundBoard 4 direct to stud wall soundproofing panel can be installed by a competent DIYer. If you don't feel confident installing the soundproofing yourself, a local tradesperson will have no difficulty. The Soundproofing Store supply comprehensive installation instructions and videos for a fuss free installation. Our expert team is also on hand to answer any questions prior, or during installation.

4. How much does it cost to soundproof a stud wall?

The cost depends on the size of the wall and the solution that's needed for your noise issue. A m² guide price is shown at the bottom of the below chart.

Stud wall soundproofing comparisons

Highlighted within this article are three excellent options for soundproofing a stud wall, depending on different levels and types of noise needing to be soundproofed.

The 3 stud wall soundproofing solutions are compared below:

Which soundproofing system should I use?

Remember soundproofing isn’t a one size fits all, it’s important to use a system that will be suitable for your specific situation to really have the greatest chance of solving that problem. If you’re unsure of which solution is best for your situation, then the best thing to do is speak to an expert. Please give us a call and speak to one of our highly trained technical advisors who can talk through the level and type of noise you are trying to block and give you the best advice. As always, we’re here to help.

Author

Ian Baker is the Managing Director of The Soundproofing Store and a leading name in the soundproofing industry.

With a prestigious track record of award-winning credentials, Ian is a trusted and respected authority in his field.

Ian is passionate about helping individuals find effective solutions to their unwanted noise issues and his extensive knowledge and insights are invaluable in helping to transform noisy environments into peaceful spaces.

Share

"We don’t expect you to become an overnight expert in soundproofing, that’s what we’re here for."