Case Study: How to soundproof a wall against noisy neighbours

ReductoClip™ Direct To Wall System Case Study for the effective soundproofing of walls against noisy neighbours

The Soundproofing Store speaks to many customers a day who are looking at how to soundproof an existing wall with the aim of reducing the noise from noisy neighbours. This wall soundproofing case study focuses on just that.

The Noisy Neighbour Issue

Mr and Mrs Billanie live in a 3-bedroom 1950’s semi-detached house and although they have a great relationship with their neighbours (we know not everyone is this fortunate) they were hearing a lot of airborne noise from next door. Anything and everything from the TV, talking and sometimes raised voices and shouting and occasionally dogs barking. Both Mr and Mrs Billanie and their neighbours also had young children in their homes and there was often the noise from the children, which is obviously expected within any family home.

As well as airborne noise, there was no carpet in their neighbour’s lounge, which meant they often heard the impact noise of footsteps on the floor. Mr and Mrs Ballanie wanted to soundproof the party wall of their lounge, which is where most of the noise from their neighbours was being experienced. Their lounge is directly opposite that of their noisy neighbours lounge.

Before soundproofing an existing wall, the following questions needed to be answered:

- The type of wall, is it a stud wall or a solid wall? - in this case it was a solid brick wall

- What is the type of noise being heard? Airborne (e.g. TV noise, conversation) or Impact noise (footsteps, doors banging) or is it a combination of both? - a combination of both

- How loud is the noise on their side of the wall? - sometimes loud levels, being able to distinctly hear clear words and conversations

- Is there a chimney on the wall? - yes, with a log burner

- If so, if you do an ear test to the chimney when hearing the noise, can you hear it coming through the chimney breast? - yes, muffled airborne noise could be heard

Does soundproofing a wall work both ways?

How does soundproofing a wall work?

- Airborne sound which is the sound wave (when a sound is created it travels through the air as a sound wave). This is blocked by mass, basically weight, so the heavier and denser a material is, the more sound it blocks.

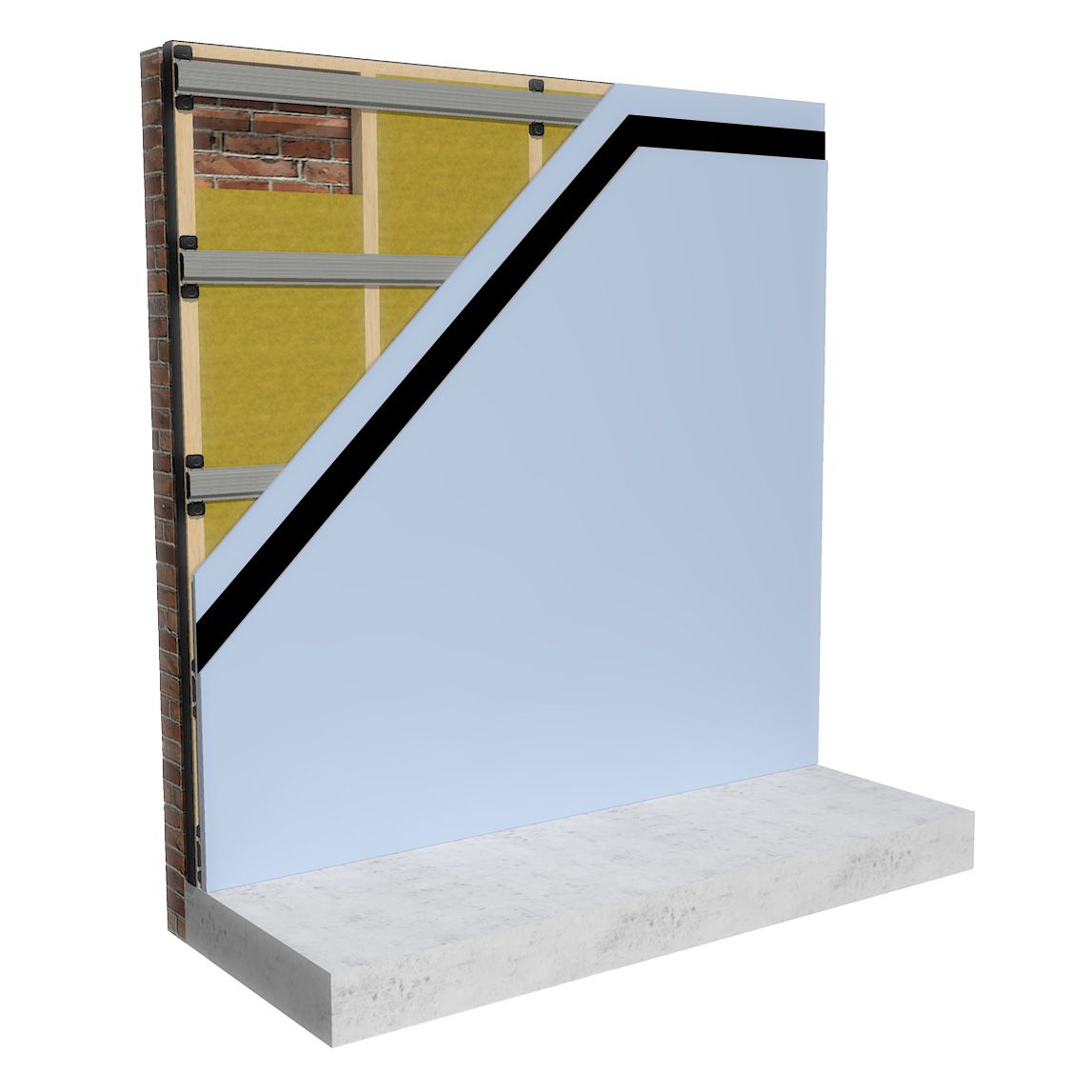

- Sound is an energy and a vibration, and both parts need to be treated to achieve the best result. This is the tricky part, because as soon as sound hits a wall the vibration travels through any solid, dense material. This energy and vibration needs to be absorbed. We will come onto the system used within this case study and why it was used, however it's worth mentioning early on, that this was achieved by installing dense material onto the ReductoClip™ Direct to Wall System. The ReductoClips make the wall flexible, meaning when the soundwave hits it, the wall can ride out that energy vibration. Like the suspension in a car.

What is the best wall soundproofing solution?

| Level of noise the solution works for | Sound reduction in dB | Thickness / space loss from original wall | How the system is attached to the wall | |

|---|---|---|---|---|

| ReductoClip™ Independent Wall System | Loud levels, can be used in recording studios | 65dB | 120mm | Requires an independent stud frame |

| ReductoClip™ Direct To Wall System | Medium to loud levels of noise | 55dB | 60mm | Applied directly to the wall |

| SoundBoard 4™ System | Medium levels of noise | 52dB | 30mm | Applied directly to the wall |

Benefits of the ReductoClip™ Direct to Wall System

- Delivering the highest level of soundproofing with minimal loss of space within the home (13mm - 17mm thinner than all other clip systems)

- Creates a room within a room, de-coupled from the existing structure - offering a high level of soundproofing

- Outstanding performance against noisy neighbours - bringing peace and quiet to the home

- The perfect solution for soundproofing against medium to loud levels of noise such as clear conversation, TV noise and music - as was being experienced by Mr and Mrs Billanie

- Suitable for use on a solid or stud wall

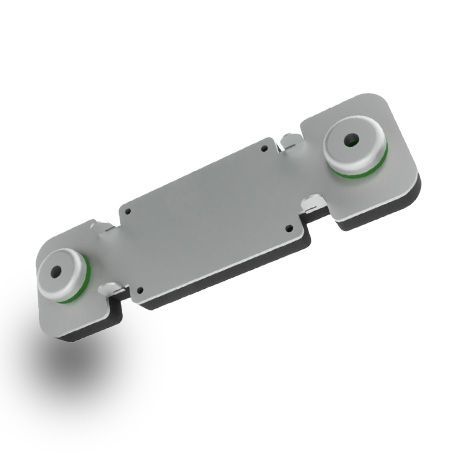

- Dual rubber design, meaning the ReductoClip is able to absorb different sound frequencies - achieving a higher wall soundproofing performance than other clips that feature just one layer of rubber

- Wider furring bars for easier plasterboard fixing - wider bars mean a larger surface area on which to attach the acoustic plasterboard, meaning an easier installation process

- Indents within the furring bars have a central and middle groove, which makes finding the midpoint on the furring bars far easier to work with when butting together the acoustic plasterboard

- Outperforms resilient bars by up to 7dB - a much higher performing system

- Exceeds Part E Building Regulations (not relevant to this particular case study)

- DIY install - can be installed by a competent DIYer or tradesperon - Mr Billanie did the whole installation himself with the help of a friend

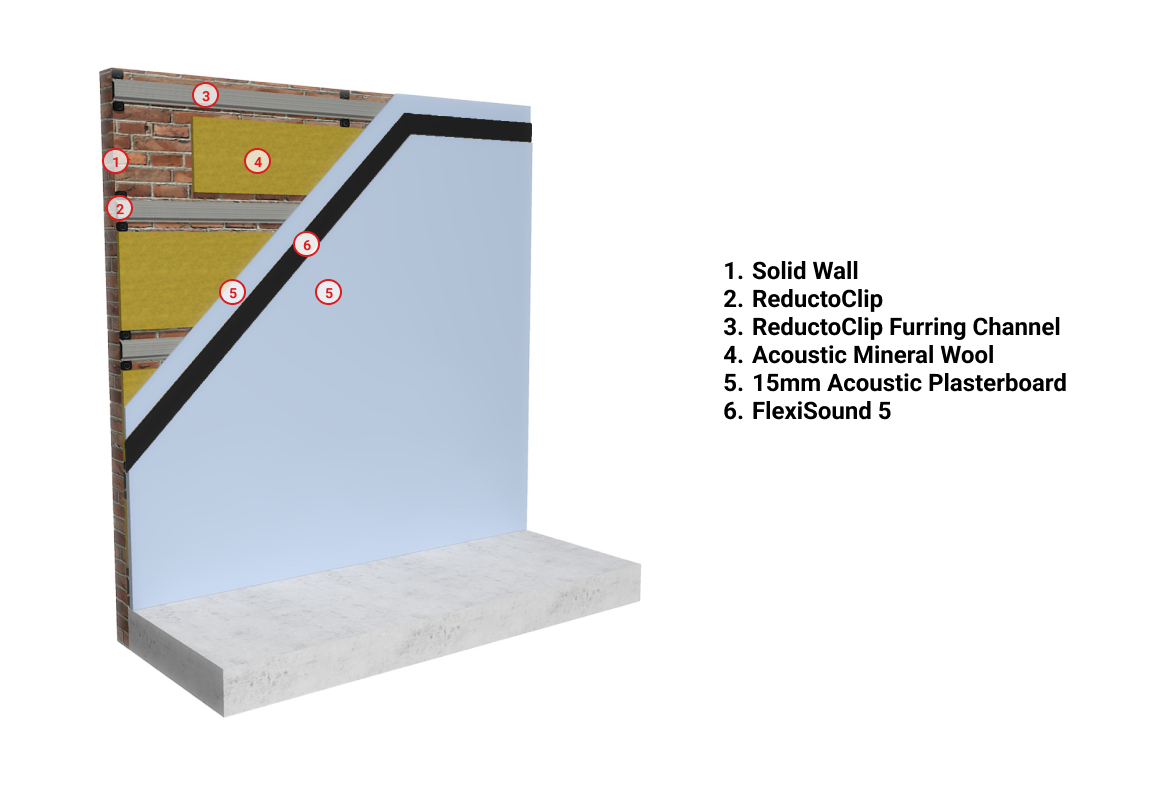

ReductoClip™ Wall Soundproofing Product Overview

What about soundproofing the chimney breast?

- In most cases the chimney breast doesn’t need the same level of soundproofing as the alcoves or wall

- Soundproofing is all about adding mass and chimney breasts are normally constructed from a double layer of fire bricks

- Fire bricks are far heavier and more dense than the standard bricks (usually) used in the alcoves

- There is often a small air gap behind and the same double layer of fire bricks on the neighbour’s side and this naturally makes the chimney more soundproof than the alcoves

Installing the ReductoClip™ Direct To Wall Solution

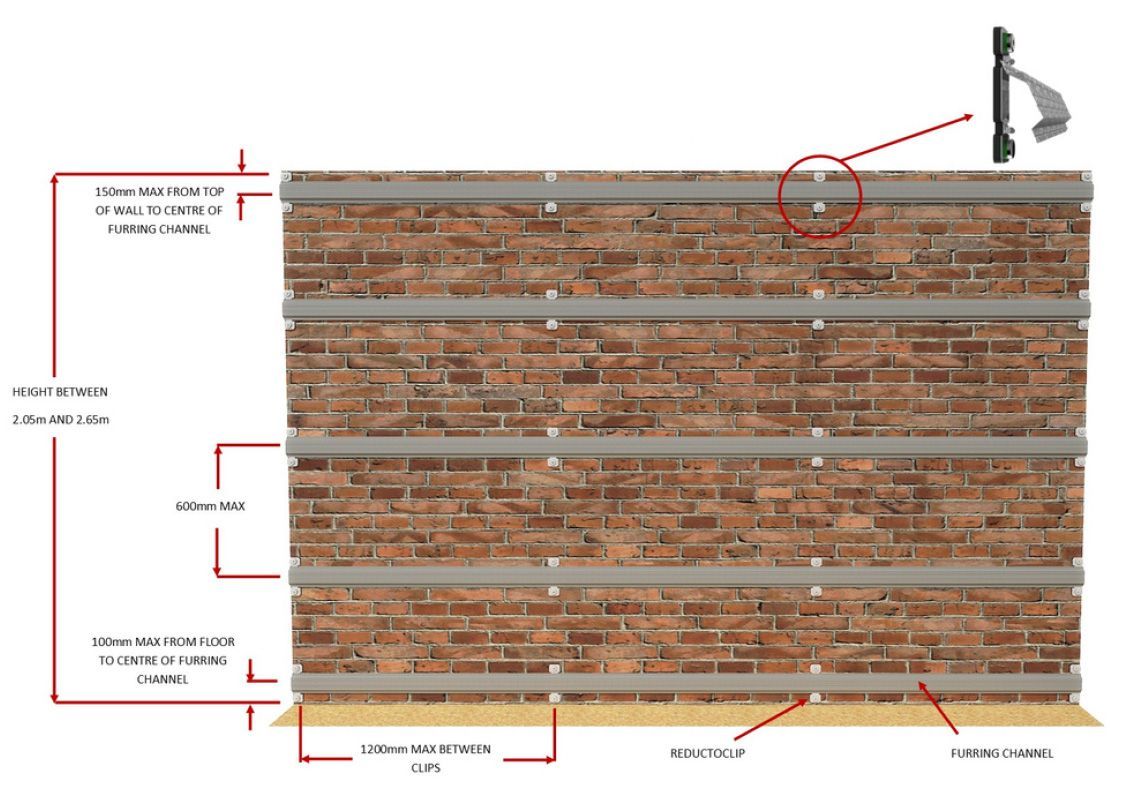

Marking out the position of the ReductoClip™ and Furring Bars

ReductoClip™ Direct To Wall Positioning Diagram

Attaching the Furring Bars

2. Next the furring channels were measured, cut and attached, ensuring they didn’t touch the edge of the wall. They were then easily installed by simply bending and releasing the furring bars within the clips.

With the furring channels, in certain cases where the wall is longer than the 3m length of the bars, or as in this case when utilising as much of the materials as possible without any unnecessary waste. Rather than using whole lengths on every section, you can overlap the bars by 150mm and secure the overlap with a couple of self tapping screws either side of the overlap.

Adding the Acoustic Mineral Wool

The first layer of Acoustic Plasterboard

Installation checklist so far

- The seams of the very first layer of acoustic plasterboard should always align at the centre of a furring channel (so two plasterboards meet on one furring channel)

- The first row of acoustic plasterboard sheets at the bottom of the wall should be installed with the long dimension supported on shims or Isolation Strip to keep the sheets off the floor

- Furring channels are installed horizontally across the wall

Acoustic Sealant is added to fill in any gaps

Adding FlexiSound 5

6. Next it was the installation of the FlexiSound 5. An extremely heavy, dense visco-elastic rubber, originally designed as a replacement for lead. Because it’s visco-elastic, this means it also dampens vibrations. It’s extremely heavy and does require two people to lift it. Being self-adhesive, it can be stuck directly to the plasterboard, requiring no fixings or secondary adhesive. The FlexiSound has a backing paper which is removed in the top corner, line it up, stick the very top part on and once the top is lined up and stuck down, the rest of the backing paper can be peeled away. The FlexiSound was stuck to the plasterboard covering the entire wall, leaving just the 5mm gap around the perimeter. TIP! It is much easier to cut the FlexiSound into smaller, more manageable pieces. FlexiSound is very sticky and is difficult to remove if stuck down incorrectly.

N.B. Mr Billanie ensured the FlexiSound was joined together without any gaps, although if you like, you can also overlap the FlexiSound to avoid gaps.

Ready for the second layer of Acoustic Plasterboard

7. The second layer of acoustic plasterboard is then installed on top of the FlexiSound 5, sandwiching it between the two layers. The second layer of 15mm acoustic plasterboard is installed as before, but by staggering the joins by starting at the opposite side from where you started, so the seams aren’t matched up.

Adding Acoustic Sealant to the perimeter

Soundproofing plug sockets

The final finish

ReductoClip™ Direct To Wall Summary

How long did it take to install the ReductoClip™ Direct To Wall System?

Decorating the wall once the system has been installed

The soundproofed wall has been redecorated

ReductoClip™ Direct To Wall Soundproofing Testimonial

Please share this article if you find it useful:

"We don’t expect you to become an overnight expert in soundproofing, that’s what we’re here for."